• GERMAN ENGINEERING MEETS AMERICAN MANUFACTURING • RUGGED DESIGNS FOR DEMANDING APPLICATIONS • PRESSURE GAUGES • THERMOMETERS • DIGITAL PRESSURE MEASUREMENT • OPTIONS TO MEET ALMOST ANY NEEDS • DEPENDABLE STOCK LEVELS

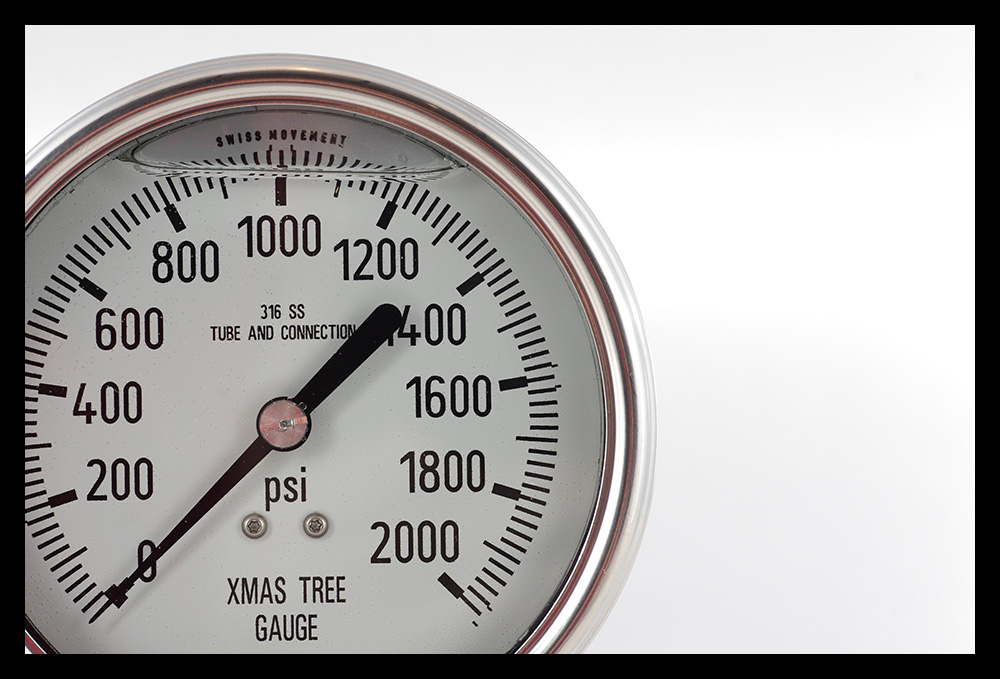

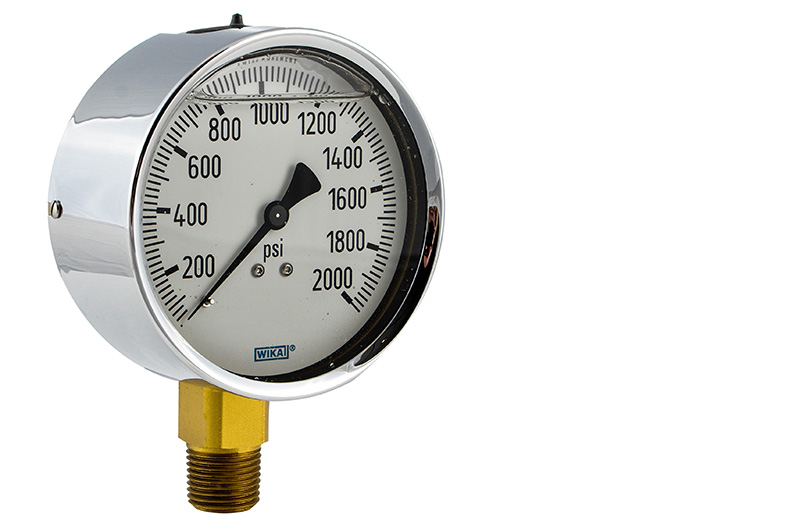

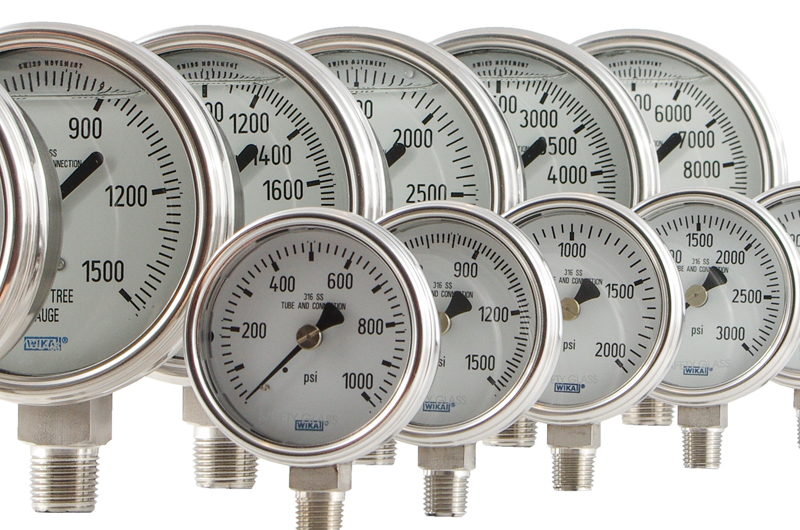

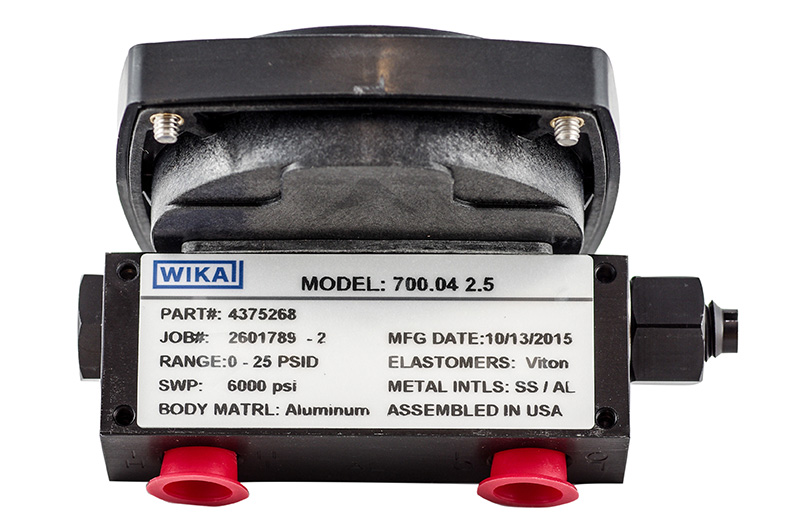

Wika Mechanical pressure gauges represent the industry standard and are designed to provide lasting service in extreme operating conditions when properly applied. Wika has pioneered many innovations over the years, resulting in a gauge for almost every application.

Wika Mechanical pressure gauges represent the industry standard and are designed to provide lasting service in extreme operating conditions when properly applied. Wika has pioneered many innovations over the years, resulting in a gauge for almost every application.